LIVE - Rebellion Reads Posts

Tattoo Cartridge | Tattoo Equipment Evolution Pt. 8

Tattoo Needles vs. Tattoo Cartridges: What is the Difference?

In earlier chapters, we explored how tattoo needles were soldered onto bars to form the basic categories and variations. These tools shaped tattooing for decades. By the late 2000s, however, a new innovation disrupted tattooing entirely: the tattoo cartridge.

During tattooing, the artist dips the cartridge tip into the ink cap, where it fills with only a fraction of a milliliter of ink — enough to run for maybe a minute before it requires re-dipping. And yet the world decided to call it a “cartridge.” The original name was module, but that didn’t travel far outside Germany. “Cartridge” sounded familiar — like a printer cartridge full of ink, or a gun cartridge packed with powder and bullet. Except ours holds almost nothing. What it does do is twist and lock into the grip, quick to load, quick to swap, and single-use. That simple motion made the name stick, and the tattoo cartridge became the standard.

When cartridges first appeared, they weren’t compatible with existing coil or rotary setups. Artists faced a decision: invest in an untested system or stick with the familiar bar-and-tube method. However, over time, the advantages became undeniable. Faster setup, greater convenience, and improved safety convinced more professionals to switch. Eventually, the industry moved almost entirely to cartridges. To understand how stroke and needle motion truly work inside tattoo machines, read What Is Stroke in Tattoo Machines?.

You can read more about how and why I decided to invest time and money and create REBEL Precision Cartridges in The Birth of REBEL Cartridges | Tattoo Equipment Evolution Pt. 9.

Tattoo Needles

Traditional tattoo needles consist of groups of needles soldered to a bar, forming a 5-inch configuration. At the end of the bar, a loop hooks directly onto the machine’s armature bar.

In this open system, the needle tips stayed exposed until full assembly. Therefore, for safe operation, artists relied on tubes — first autoclavable stainless steel, later disposable plastic by the 2010s.

Using needle bars also demanded heavy preparation. Before pre-made disposables became available in the 1990s, artists soldered, cleaned, sterilized, and reassembled their tools. Even with disposables, the setup remained bulky. As a result, artists often needed multiple machines and several power supplies for each session.

The classic tattoo needle on bar — steel soldered and built to drive ink with controlled precision.

Tattoo Cartridge and Its Operation

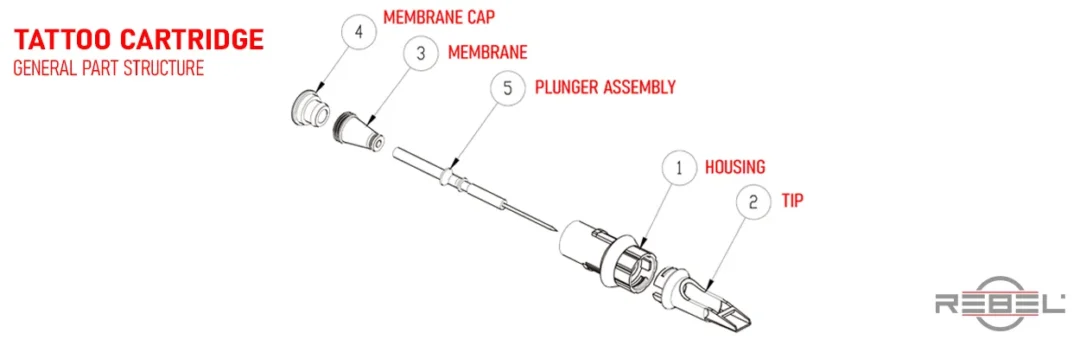

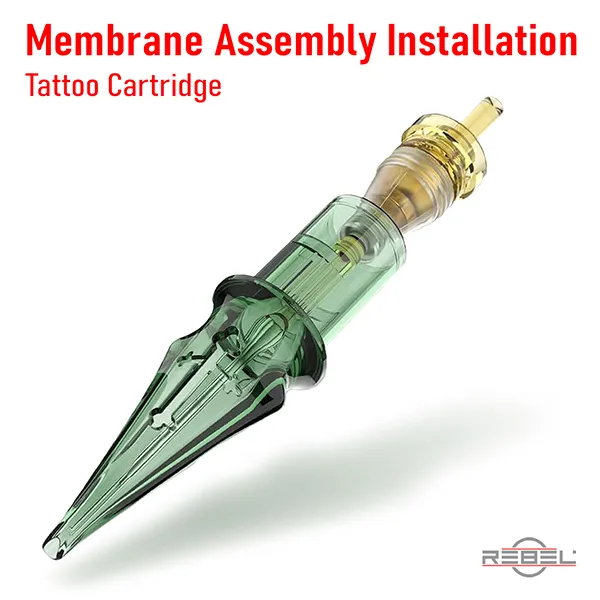

A tattoo cartridge is a compact, 2.5-inch pre-assembled mechanism that safely houses the needles. The needle configuration is fixed into a plastic plunger, seated within a housing, and sealed by a membrane cap.

When the machine’s push rod presses against the plunger, the needle tip extends from the cartridge to penetrate the skin. As soon as pressure stops, the membrane retracts the needles safely back inside. For smooth operation, continuous contact between the plunger bar tip and the push rod is essential for best performance.

The machine pushrod drives the outward movement of the needle, while the retracting mechanism returns it. In other words, rotary tattoo machines measure speed in Hertz (Hz) — not in Volts like coil machines.

In practice, most rotary tattoo machines operate between 50 Hz and 150 Hz, which equals roughly 3,000–9,000 cycles per minute (RPM). This frequency directly reflects how many times per minute the needle penetrates the skin during tattooing.

-

- Lining: typically 120–150 Hz / 7,000–9,000 RPM for faster penetration and cleaner lines.

- Shading & Packing: usually 60–100 Hz / 3,500–6,000 RPM for softer hits and smoother fills.

Altogether, this overview explains how the tattoo cartridge functions at a practical level. For a deeper dive into the physics — including how rotary-to-reciprocating motion converts circular drive into vertical needle travel, how vibration affects performance, and how these factors shaped the creation of REBEL Precision Cartridges — see Part 9: The Birth of REBEL Cartridges.

Definition of Tattoo Cartridge

A tattoo cartridge — also called a tattoo needle cartridge — is a pre-assembled, disposable housing unit containing a group of tattoo needles, designed for use with modern tattoo machines.

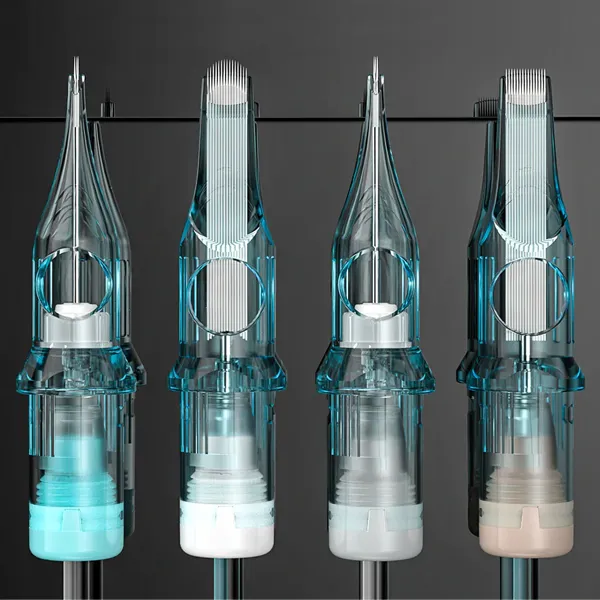

Tattoo Cartridge Features and Components

Tattoo cartridges are safe, disposable, and efficient. Their design integrates the traditional 5-inch bar-and-tube system into a compact 2.5-inch module.

Core components include:

-

- Plunger assembly

- Retracting mechanism – Membrane

- Membrane cap

- Housing

- Needle stabilizer

This structure integrates the traditional needle bar system into a compact, safe, and disposable module.

Let’s examine each component and its function in detail.

Plunger Assembly – The Heart of the Tattoo Cartridge

Function: Delivering ink to the skin consistently in the exact shape of the needle configuration.

This assembly is the true heart of the tattoo cartridge, and it determines roughly 80% of the cartridge’s quality. In fact, it directly defines your line work. The plunger assembly is built from two fixed parts:

-

- A stainless-steel needle head configuration

- A plastic bar called the plunger

1. Needle Head – the number of needles soldered together into a specific shape to create the desired tattoo needle configuration (RL, RS, M, CM).

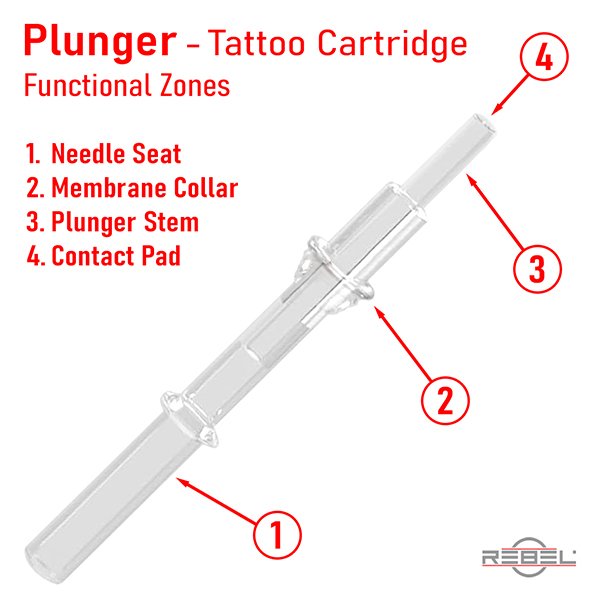

2. The plunger is the internal plastic bar that contacts the machine’s pushrod, and it has four functional zones:

-

Needle Seat – where the needle head attaches

-

Membrane Collar – secures the bottom of the membrane in place

-

Plunger Stem – the visible section of plunger that connects to the pushrod and influences stroke depth

-

Contact Pad – the surface that contacts the pushrod ball

The greatest challenge isn’t the plastic itself but the bond between stainless steel and plunger. At 150 Hz, a tattoo machine generates extreme vibration and shear, so only a high-strength, vibration-resistant adhesive can survive. If the bond fails, the needle may detach mid-tattoo — a catastrophic risk. Furthermore, plunger stem length directly controls how far the needle projects relative to the machine’s fixed stroke, making precision in this dimension essential.

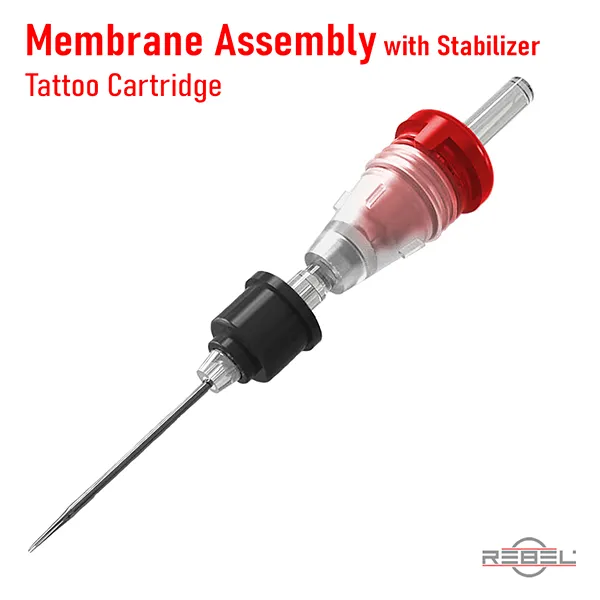

Tattoo Cartridge Membrane System – Retracting Mechanism

Function: Dual role: pull the needle back and prevent ink backflow.

The push rod can only drive needles outward; it cannot return them. That makes the retracting mechanism essential. At the same time, the membrane system prevents contaminated ink and blood from reaching the grip. In other words, two birds with one stone.

-

- If the material fails, the needle may remain exposed and unusable.

- If there’s no seal, contaminated ink can flow backward into the machine grip.

Over time, manufacturers tried alternatives like springs or rubber bands. However, these caused noise, poor sealing, and hygiene risks. Today, medical-grade silicone membranes dominate because they are durable, silent, and reliable.

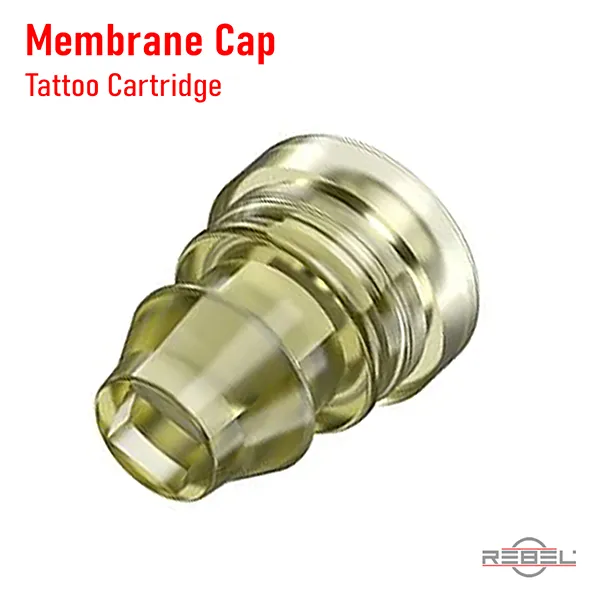

Membrane Cap – Sealing the Cartridge

The membrane cap seals the cartridge chamber and fastens the membrane’s top part. Materials vary, but many brands color them for visual differentiation.

Housing – Structure and Stability

Function: Drive the needle and hold all components in place.

The cartridge tip shape affects ink flow and line quality. Materials don’t endure as much stress as membranes or adhesives, but poor-quality plastic can grind into microparticles that enter the skin. Consequently, medical-grade resins are preferred.

Tattoo Cartridge Housing Types

-

- One-piece housing: fixed tip, harder to clean clogs.

- Two-piece housing: removable tip, easier to clean, more flexible.

Tattoo cartridge housing manufacturing offers high customization for branding. In fact, as long as chamber dimensions are maintained, engineers can design shapes, textures, or colors.

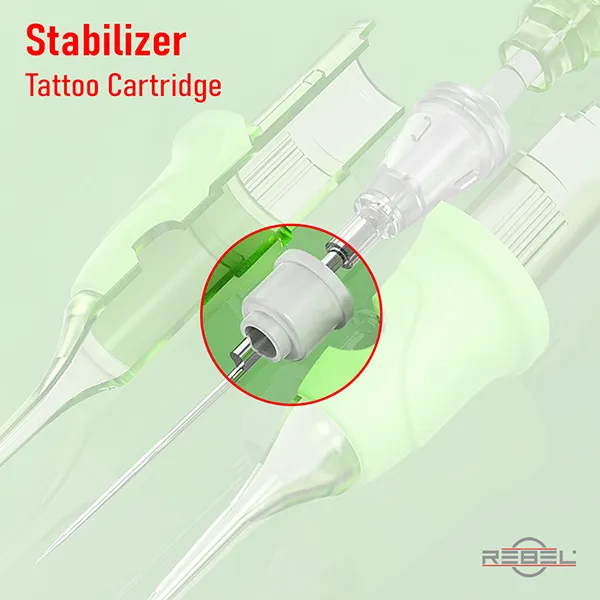

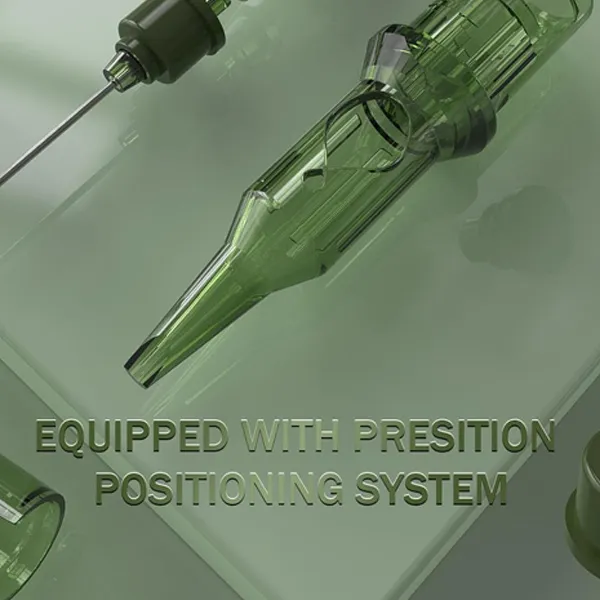

Tattoo Cartridge Stabilizer – Round Needle Configuration Support

Function: Keeps round needle configurations centered, ensuring crisp, sharp lines.

Magnums don’t use stabilizers. Instead, they rely on side nibs above the retraction line, and consequently, these prevent excess movement during tattooing.

Full Cartridge Assembly

When all components come together — needle head, plunger, membrane, stabilizer, and housing — they form the complete tattoo cartridge. This integrated system ensures precision, safety, and compatibility across professional setups, ready for work straight out of the blister pack.

Symptoms of Unfit Measurements

-

- Plunger too short: causes noisy hammering as the pushrod hits repeatedly.

- Plunger too long: keeps the needle constantly exposed, risking safety.

- Grip interface too small: cartridge vibrates loose and falls out.

- Grip interface too wide: cartridge won’t fit into grip.

- Housing tip poorly shaped: weak ink flow, resulting in faint lines.

In short, when tolerances are off, both safety and performance suffer.

Core Features That Define a Quality Cartridge

-

- Needle quality and soldering → line quality.

- Retracting mechanism → durability and contamination control.

- Needle-to-plunger bond → can it survive a 5-hour session?

- Tip geometry and materials → ink pickup, stability, and flow.

Setting the Standard

Before Cheyenne (pre-2007), there were scattered attempts to modularize tattoo needles, but nothing safe or standardized. Most lacked membranes, proper locking, or sizing.

That changed in 2007, when Cheyenne introduced the Hawk rotary machine with its cartridge system. It was a massive risk: artists had to abandon familiar bar-and-tube setups for a machine with no track record. Yet, Cheyenne’s design locked in the operational standards we still use: grip interface measurements (length and diameter),bayonet grip lock, , plunger stem, and membrane seal.

Cheyenne’s blueprint became the backbone of the modern tattoo cartridge system. As a result, cartridges went on to dominate the industry worldwide.

Grip Interface – Cheyenne Bayonet Lock for Tattoo Cartridges

The grip interface with Cheyenne’s bayonet lock defines how cartridges attach to the machine grip. In 2007, Cheyenne introduced this quick-twist system with the Hawk, setting the first true operational standard for tattoo cartridges. Before that, there was no widely used cartridge system in tattooing — only scattered, unsafe experiments that never gained traction. Cheyenne’s design gave cartridges their universal dimensions in grip diameter and locking, allowing cross-brand compatibility. Today, nearly all cartridges follow this blueprint, not by agreement, but by necessity: if manufacturers want their cartridges to sell, they must fit Cheyenne-standard grips.

Membrane – Retracting and Backflow Prevention

The silicone membrane inside the cartridge serves two roles: it retracts the needle when pressure stops, and it blocks contaminated ink or fluids from flowing back into the grip. Before Cheyenne, many prototypes used springs or bands with no real safety seal. The membrane became the gold standard for hygiene and is now non-negotiable in any professional cartridge.

Plunger Stem – Push Rod Contact Point

The plunger stem is the plastic bar that extends about 10 mm beyond the cartridge housing to meet the machine’s push rod. Cheyenne set this length as the standard so the push rod always makes clean, consistent contact. If the stem is too short, the connection fails; if it’s too long, the needle overextends. Since every machine has a fixed mechanical stroke, the stem’s length directly affects how much the needle can safely project from the cartridge tip. This makes the plunger stem a critical factor in both performance and safety

Market Chaos

Once Cheyenne proved the concept, every manufacturer wanted a piece of the market. Companies rushed in with their own designs, often inventing names for parts without knowing the original terms, and layering on overlapping features. The result was a fragmented market that left artists confused and forced to navigate inconsistency across brands.

The result is today’s cartridge chaos: inconsistent terms, varying tolerances, and even a flood of patents. These patents don’t represent the invention of cartridges, but refinements. Instead, they demonstrate both the reach of Cheyenne’s breakthrough and the messy growth that followed.

Official Tattoo Cartridge Component Parts vs. Market Mislabels

During my research for this article, I came across thousands of tattoo cartridge images — and honestly, some of them made my day. Let me return the favor by sharing a few of my incredible “professional” findings. I didn’t find this entertainment at the local strip club, no… I found it on Amazon.com. All I had to do was type “professional tattoo cartridges” into the search bar, and voilà — comedy gold. If you’re ever having a bad day, my friend, just give it a try. 🙂

1. Housing – The Cartridge Shell

-

Mislabels found online: “Needle shell,” “High Wear-resisting PVC Material,” “Needle cap,” “Outer cover,” “Wear Resistant PVC Material Shell,” “PVC body,” “Plastic tip.”

-

Problem: Many brands confuse the housing with the tip or simply rename the entire body with whatever material they used (PVC, ABS, medical plastic).

2. Plunger Assembly

-

Mislabels found online: “Striker bar,” “Needle bar,” “Needle rod,” “Solderless Kit Design,” “Limit device,” “Push bar.”

-

Problem: The plunger is plastic, while the needle grouping is stainless steel — mislabeling them together as “needle bar” confuses artists into thinking it’s the same as the old bar-and-needle system.

3. Retracting Mechanism (Membrane System)

-

Mislabels found online: “Silicone rebound ring,” “Silicone adhesive Tape,” “Rubber band system,” “Rebound pad,” “Silica gel.”

-

Problem: Calling truncated cone shape sealing membrane a “ring” or “gel” misleads artists about safety. Some brands even hide the fact that membranes prevent backflow.

4. Membrane Cap

-

Mislabels found online: “Needle cap,” “Plug,” “Tail Plug,” “Top cover,” “Stopper.”

-

Problem: “Needle cap” especially confuses this with the protective caps used for pre-sterilized tattoo needles.

5. Stabilizer

-

Mislabels found online: “Positioning system,” “Stabilizing device,” “Inner Rotation Oval buckle,” “Limit Device,” “Positioning Firmware,” “Centering ring”.

-

Problem: Brands over-engineer the naming (like “precision positioning system”) to sound high-tech satellite system.

6. Grip Interface

-

Mislabels found online: “Rotation lock,” “Click system,” “Snap-fit,” “Needle buckle.”

-

Problem: Cheyenne standardized this, but copycats rename it, making artists think there are multiple incompatible systems — when most are just derivatives of the bayonet lock.

7. Needle Head – Soldered Needle Groups

-

Mislabels found online: “Needle thread,” “Needle point,” “Solderless kit design,” “Needle bar head.”

-

Problem: “Needle thread” and “solderless kit” are amateur marketing terms that sound like cheap mechanical toys, not precision medical-style instruments.

Takeaway for Market Chaos Section:

The official cartridge has 5-7 main parts (Housing — one- or two-piece, Plunger, Needle head, Membrane, Membrane Cap, Stabilizer). However, what you see online are dozens of amateur rebrands: “oval buckle,” “silica gel,” “striker bar,” “limit device,” “rebound ring,” etc.

This proves the point: Cheyenne set the standard, but unfortunately, the wannabes created a vocabulary mess.

Tattoo Cartridge Evolution – Why Artists Switched

Tattooing grew from underground culture to mainstream art in the late 20th century. At the same time, safety standards tightened. Demand for faster and safer tools drove the rise of cartridges.

Coil machines with needle bars required multiple setups — often 4–5 machines, each with its own power supply and footswitch. Breaking them down after a session carried high risks of cross-contamination.

By contrast, cartridges cut setup time to seconds. Two machines — one for lining, one for shading — could handle everything. Artists simply swapped between cartridges. Consequently, the result was compact, quiet, and efficient.

Tattoo Cartridge Safety Benefits

Tattooing always carries risks for both artist and client. Artists risk accidental needle sticks; clients risk cross-contamination.

Cartridges reduced these risks dramatically. In addition, hygiene improved across the industry. Needles retract automatically when the machine stops, and each cartridge is single-use and sterile. As a result, hygiene improved across the industry.

Today, cartridges are the global standard. Artists never reuse them, and each unit serves one client only.

For more on safe practices, see the FDA’s guide to tattoo safety.

Conclusion

The evolution from needle bars to cartridges transformed tattooing. Cartridges didn’t just make tattooing safer — they also made it far more efficient. By the early 2020s, silicone-membrane cartridges dominated the market worldwide.

Still, at the heart of every cartridge is the craftsmanship of the needle itself. Cartridges elevated that foundation into a modern, safe, and brilliantly functional system. Ultimately, they became the defining standard of modern tattooing.

Read On

This chapter marks the turning point in the Tattoo Equipment Evolution series. In Part 9, we’ll reveal The Birth of the REBEL Cartridges — engineered to take precision and safety even further.

Spread the Knowledge

If this article helped you, share it with fellow tattoo artists and let’s keep elevating the industry together.

Explore REBEL Precision Cartridges

For artists ready to elevate their work, browse the full range of REBEL Precision Cartridges — engineered for safety, consistency, and efficiency.

Your Voice Matters – Leave a Comment

Got questions or insights about today’s topic? Drop them in the comments — your voice helps push the craft forward.

◦ Caesar The Hun