LIVE - Rebellion Reads Posts

REBEL — The Apex of Tattoo Cartridges | Tattoo Equipment Evolution Pt. 11

REBEL Precision Tattoo Cartridges — The Apex

REBEL The Apex of Tattoo Cartridges marks the point where tattoo equipment finally caught up with real-world expectations — precision performance without inflated pricing. Tattoo tools have evolved from handmade needles to modern cartridges, and through each stage, one truth remains — artists want consistency they can afford.

Built for artists who refuse to compromise — and even more importantly, refuse to overpay. Moreover, they demand tools that keep up with their pace.

Every REBEL cartridge delivers steady ink flow, predictable movement, and comfort that lasts the entire session — therefore, it gives artists the control they demand. That’s what makes it the Apex of tattoo cartridges — not marketing, but proof through performance.

For Precision Driven Tattooing

Inside REBEL Precision Tattoo Cartridges — Built for Apex Performance

From the very beginning, my goal was clear: to create cartridges that combine affordability and performance. Every membrane, every solder, and every material choice has a deliberate reason — to deliver stability, predictability, and surgical precision.

This is not theory. Rather, it’s the result of decades of testing on real clients and in real sessions. Consequently, REBEL Precision Tattoo Cartridges have proven themselves as reliable tools that maintain precision over time.

“If a cartridge can’t perform under pressure, it doesn’t belong on my station.” — Caesar The Hun

In practice, if a cartridge fails once, it never earns a second chance.

Ultimately, true precision is never claimed — it is earned through consistency. And in the end, reliability always reveals who takes the craft seriously.

Building REBEL Precision Tattoo Cartridges — The Apex of Modern Tattoo Tools

REBEL Precision Tattoo Cartridges are built from experience, not shortcuts. As a result, reliability becomes the foundation for every REBEL cartridge. They reflect thousands of hours in the chair where reliability defines success. Therefore, when an artist chooses REBEL, they join the rebellion against mediocrity.

Additionally, every order represents more than a product; it stands for discipline and respect for the craft. Furthermore, each box communicates one clear message: precision and performance come first. For that reason, REBEL exists to serve professionals who value dependability as much as creativity.

To that end, let’s look at the foundations that shaped the Apex.

REBEL Precision Tattoo Cartridges at the Apex of Consistency

As explained in Birth of REBEL Cartridges | Tattoo Equipment Evolution Pt. 9, my checklist was demanding yet straightforward. Each requirement became a building block in creating what I call the apex of tattoo cartridges.

-

Affordable pricing

-

Consistent high needle quality

-

Classic two-piece housing

-

Options for customization

-

Branded packaging

-

Reliable manufacturing turnaround

Together, these points form the foundation that separates REBEL from every other brand. As a result, the outcome was a cartridge that performs exactly as a professional expects — every single time.

1. Affordable Pricing

Price doesn’t define professionalism — but bad math can ruin it.

My aim was to build a dependable workhorse cartridge, not a collector’s item. By doing so, REBEL cartridges stay in the mid-price range, striking a balance between affordability and professional-grade reliability. They’re made for artists who count every dollar of every session, not for companies that count profit margins.

Admittedly, cheaper cartridges exist; however, in practice they often come with inconsistent quality or unreliable availability. When that happens, professionals are forced to switch brands and risk inconsistency in their work. REBEL gives you something better: the stability you can afford to rely on.

Consequently, artists can focus entirely on tattooing, not on supply issues.. Ultimately, it’s one less distraction in a craft that already demands full focus.

2. Consistent High Needle Quality – The Apex Performance

Our manufacturing partner continues to meet REBEL’s strict expectations for quality, safety, and consistency. Each batch matches the last, ensuring identical needle performance year-round.

Every REBEL cartridge includes:

- Medical-grade PC (polycarbonate) housing for strength and stability.

- Medical-grade UV adhesive for a secure, long-lasting steel-to-plastic bond.

- High-tensile silicone membranes — a high-performance, flexible compound that keeps rebound pressure consistent even through long sessions, after hundreds of thousands of flex cycles.

In addition, all materials comply with professional safety standards, reinforcing REBEL’s commitment to both performance and precision. For better understanding your tool, explore Tattoo Cartridge | Tattoo Equipment Evolution Pt. 8.

3. Tattoo Cartridge Housing Choice

I deliberately ignored market trends because conviction mattered more than popularity.

The decision for a two-piece housing had two driving factors: to pay respect to Cheyenne’s 2007 breakthrough, and ensuring the practical advantage of removable tips for quick cleaning during long sessions — something one-piece systems cannot offer.

As a result, this choice redefines convenience without sacrificing control. As a result, the design provides flexibility, efficiency, and full control. Likewise, the two-piece format upholds the mechanical precision REBEL cartridges are known for. Meanwhile, it also saves time when cleaning between color transitions.

4. Black Jacket, Red Tie — The Classic REBEL Precision Tattoo Cartridge Look

Performance should look professional. That’s why REBEL cartridges wear their identity like a uniform — black jacket, red tie, classic look.

- The black housing represents focus and durability,

- the red membrane cap signals precision and rebellion,

- and the clear tip keeps visibility absolute.

In essence, this color scheme tells the story of function meeting identity.

Consequently, each cartridge instantly communicates professionalism and trust. In turn, the look becomes part of the function.

REBEL — The Apex of Tattoo Cartridges

In the end, the Apex isn’t a product line — it’s a standard.

REBEL cartridges earned that title because they deliver where others don’t: in real sessions, with real clients, where reputation is on the line. They’re not marketed to hobbyists or collectors — they’re built for the working pros who need every pass to count.

Price, performance, and consistency — that’s the real hierarchy of tattooing. And REBEL stands at the top of it.

“They run clean, they load right, and they never surprise you mid-line.” — REBEL artist testimonial

Moreover, extensive field testing under real-world conditions shaped every refinement, so each adjustment came from proof, not assumption. From long sessions to high-speed color packing, REBEL cartridges consistently delivered clean lines and predictable ink flow — the traits professionals value most.

Because of these qualities, the REBEL Precision Cartridge is not just a product — it’s the result of experience and rebellion against compromise. Consequently, it’s the workhorse of professional tattooing, built for high-volume shops and private studios alike. For that reason, it has become the standard others try to meet.

REBEL Precision Tattoo Cartridge Apex Components

Every REBEL cartridge is built with precision-engineered components that define its reliability:

-

Black medical-grade polycarbonate (PC) housing — impact-resistant and stable under pressure.

-

Clear medical-grade polycarbonate (PC) tip — ensures full needle visibility for controlled ink flow.

-

UV-bonded stainless-steel needle head to medical-grade polycarbonate plunger — a high-endurance fusion that maintains alignment over time.

-

High-performance silicone membrane — delivers consistent rebound pressure through every stroke.

-

Red medical-grade polycarbonate (PC) membrane cap — seals the assembly and symbolizes the REBEL identity.

Together, these components achieve what professionals call Apex precision — strength, clarity, and control without compromise.

Tested. Trusted. Proven.

-

1 cartridge return out of 1,171 completed orders

-

5 years of zero membrane failures.

-

100% sterile, EO gas–validated packaging.

-

Trusted by professionals in 38 U.S. states.

From here, the manufacturing process shows how these components come together — and why every REBEL cartridge performs predictably.

Inside the REBEL Precision Tattoo Cartridge Manufacturing Process

Next, the manufacturing process turns design into reliability — the difference between guessing and truly knowing your tools. Manufacturing is where the REBEL becomes the Apex, where design turns into reliability you can feel in every session.

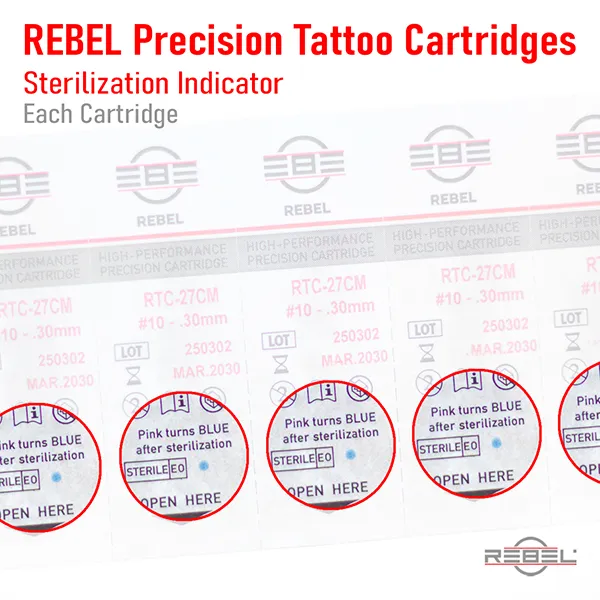

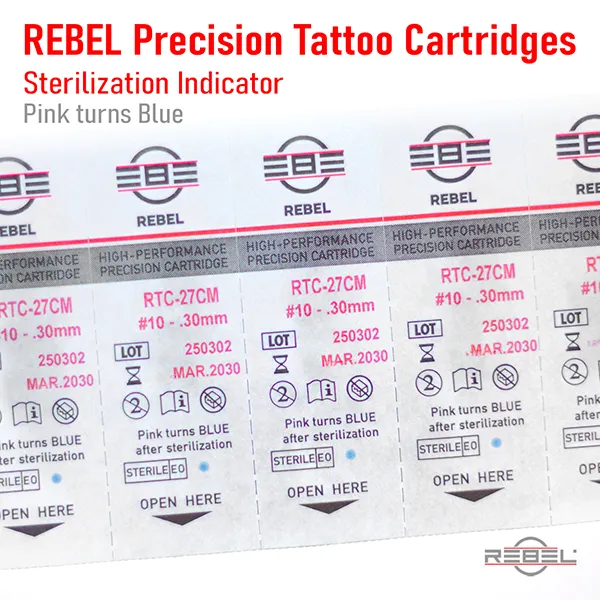

Step One: Blister Sealing and Quality Control

After assembly, each REBEL Precision Cartridge is manually inserted into a five-slot blister tray. The hot-sealing process is automated for accuracy and consistent pressure.

The back of every blister is sealed with medical-grade dialyzing paper — adhesive on one side, REBEL branded print on the other with product data, lot number, and design details.

This paper also carries a chemical sterilization indicator dot that confirms the final sterilization stage and perforation for easy separation.

Step Two: Packaging and Labeling

Once sealed, these 5-cartridge blister sheets are hand-loaded into REBEL’s signature black paper, silver and red foil printed custom drawer boxes. Each drawer includes a small label showing the product code and expiration date.

These boxes are then grouped into retail sets of 10 or 20 cartridges, matching REBEL’s standard market packaging.

Step Three: EO Gas Sterilization

Finally, the retail boxes are packed into a master carton and transferred to an Ethylene Oxide (EO) gas sterilization specialized facility.

During this process, the gas penetrates the carton, passes through the retail boxes, and reaches the cartridges via micro-perforations in each blister tray, ensuring complete sterilization.

When the cycle finishes, the indicator dot turns from pink to blue, confirming successful sterilization.

The REBEL Precision Tattoo Cartridge Standard of Performance

This is how every REBEL cartridge reaches its final form — assembled by precision, sealed by automation, verified by science.

It’s not about showing off the process; it’s about giving artists a clear view of the tools they trust their name and reputation with.

For more about cartridge construction and precision components, read Tattoo Cartridge Manufacturing | Tattoo Equipment Evolution Pt. 10.

The REBEL Precision Tattoo Cartridge Range

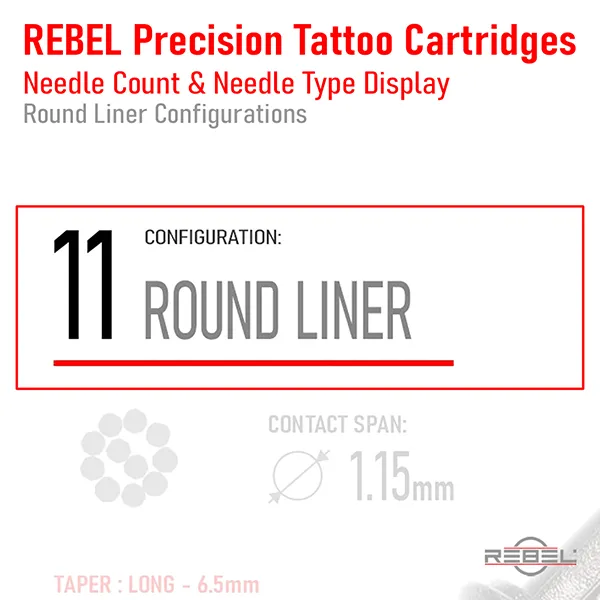

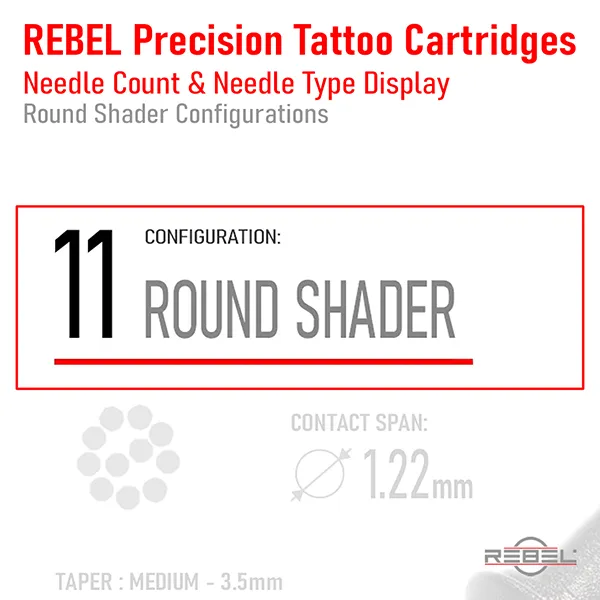

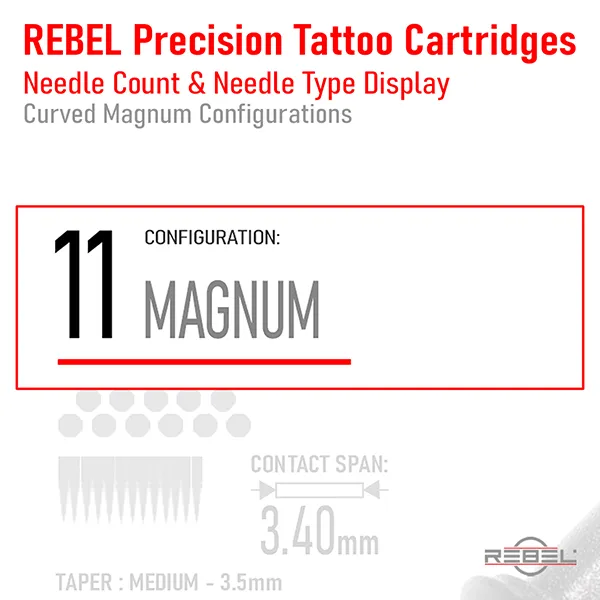

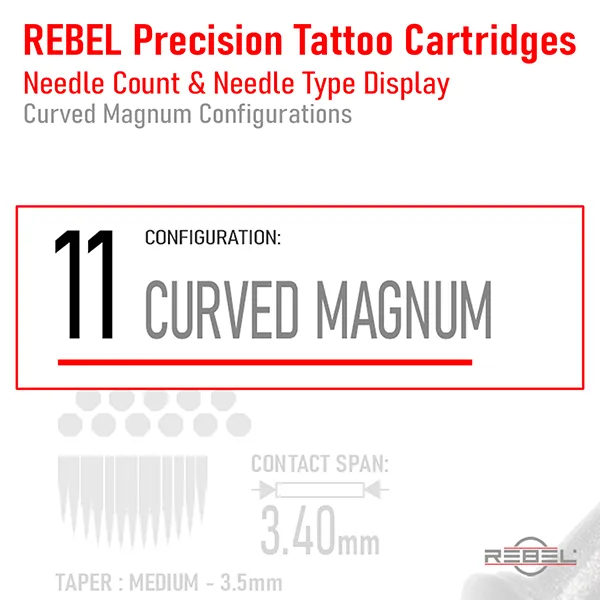

From precision liners to curved magnums, REBEL offers every essential configuration:

-

Precision Liner

-

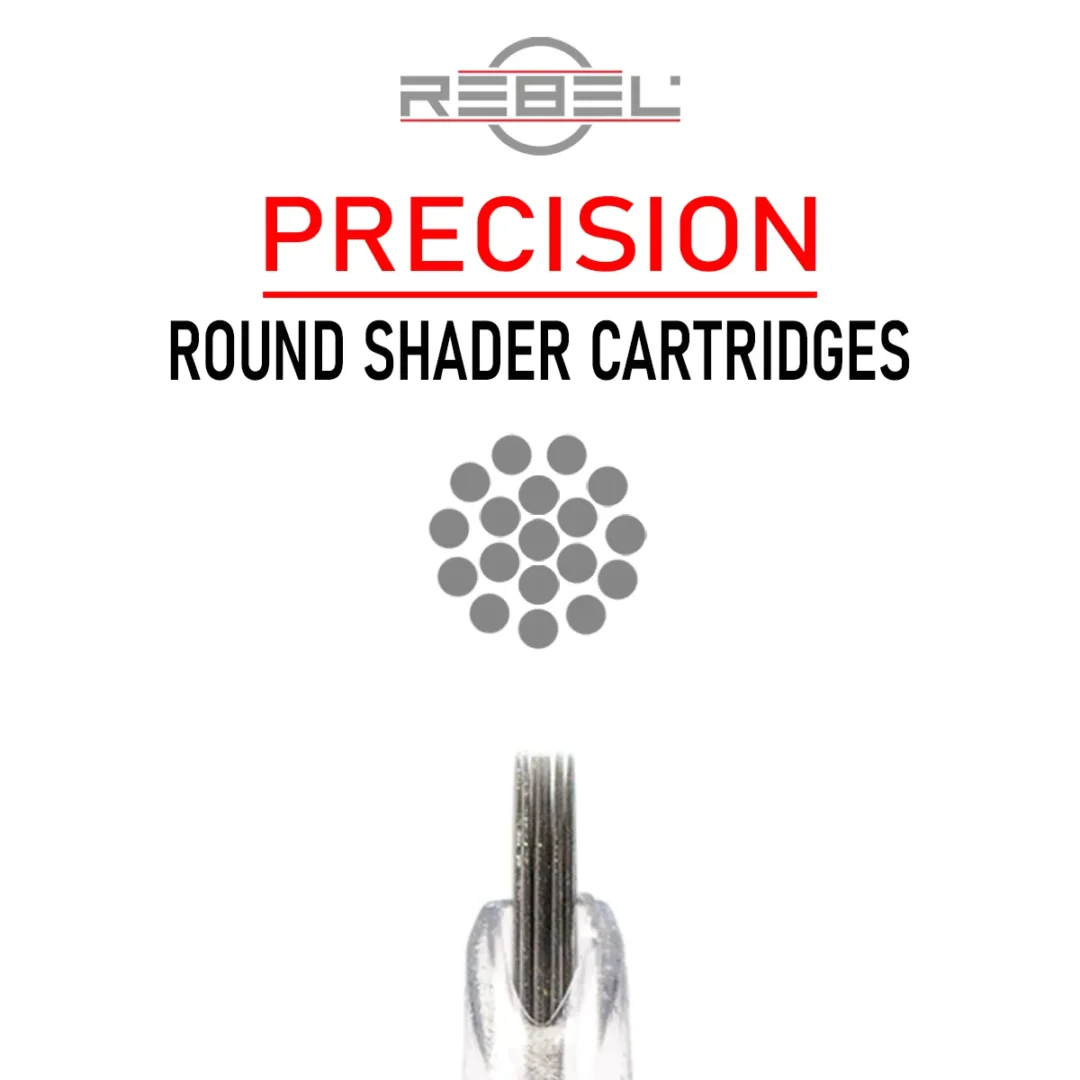

Round Shader

-

Magnum

-

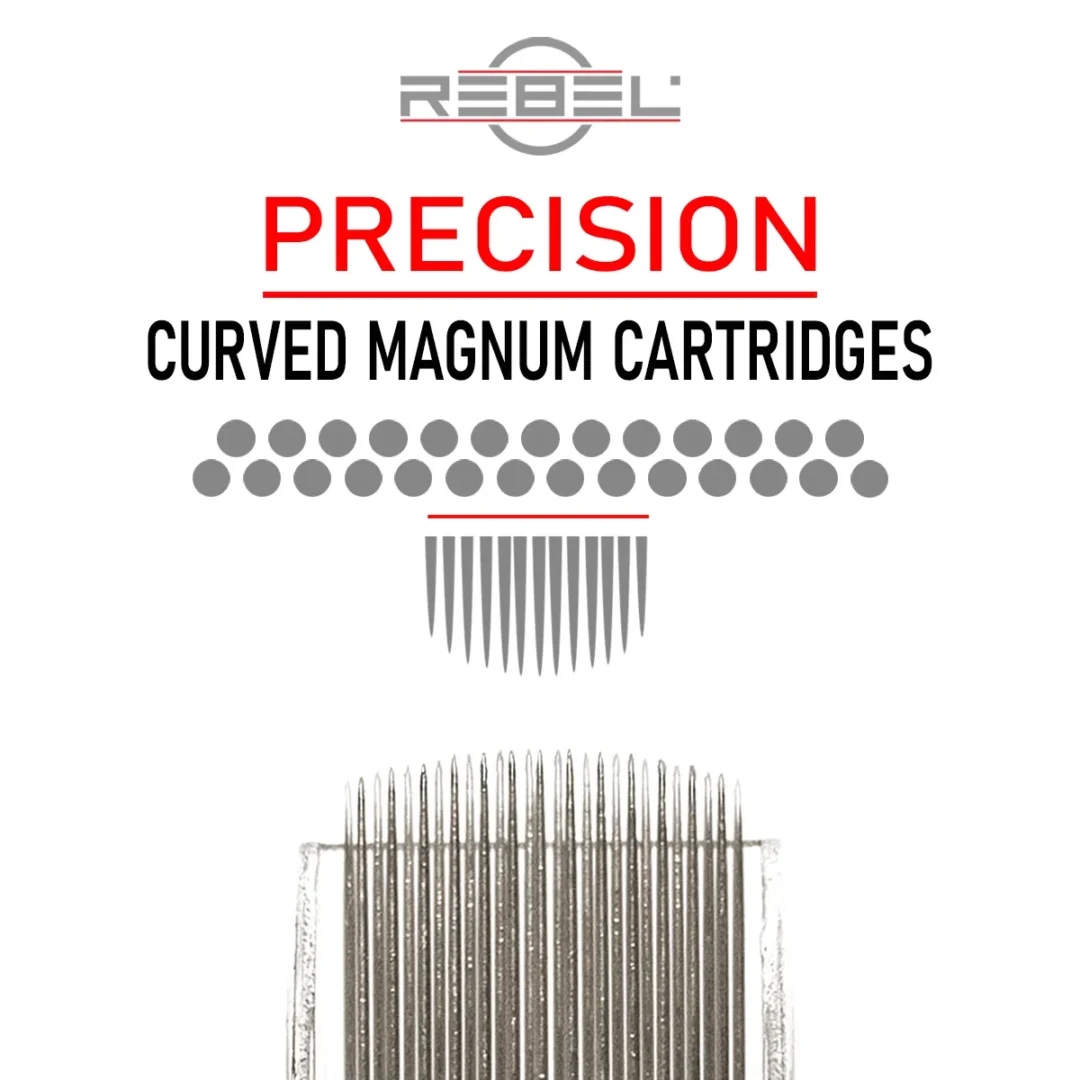

Curved Magnum

In the end, each configuration earns its place. For example, liners carve precision. Shaders shape tone. Magnums move ink like machines. Curved magnums? They blend what others can’t touch. That’s not variety for show — it’s function by design.

The Apex Standard — REBEL Precision Tattoo Cartridges Explained

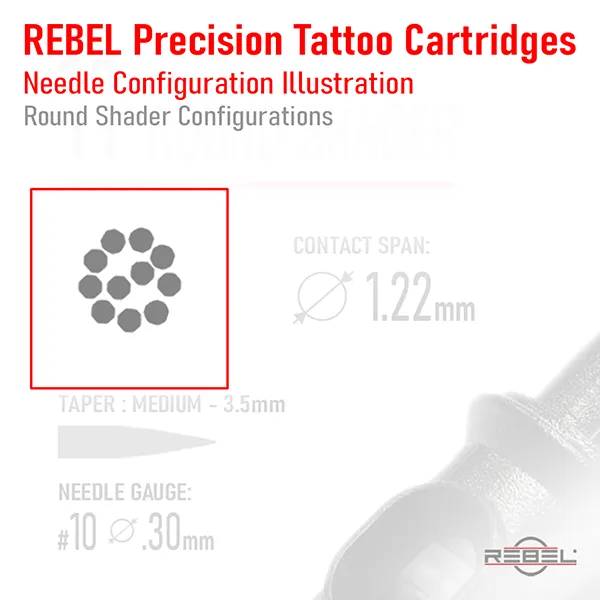

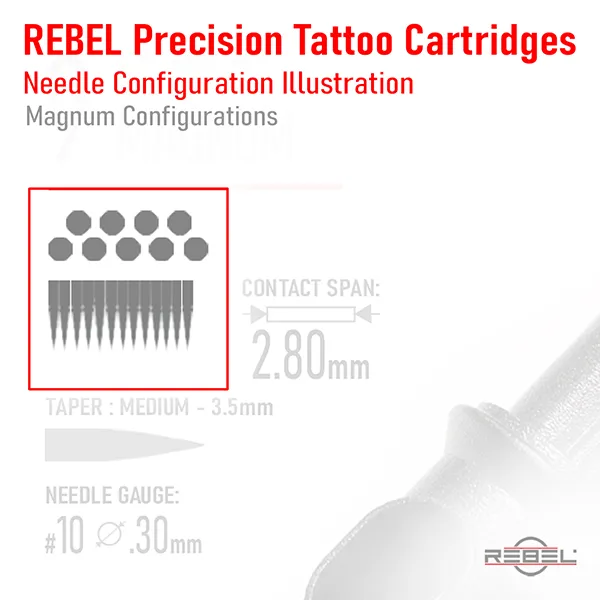

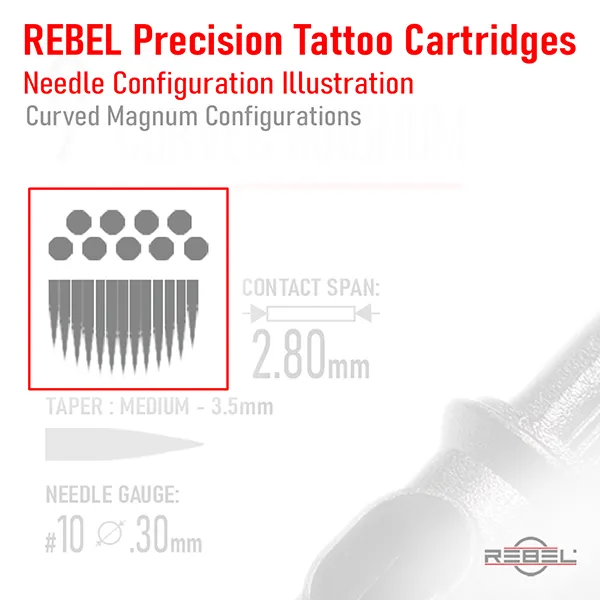

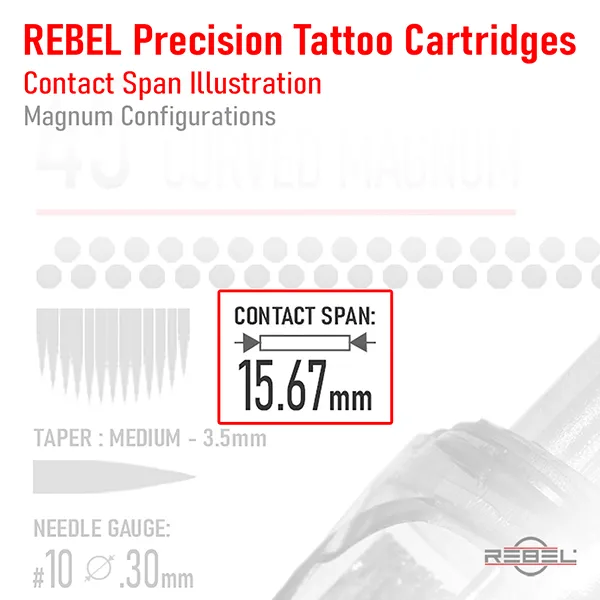

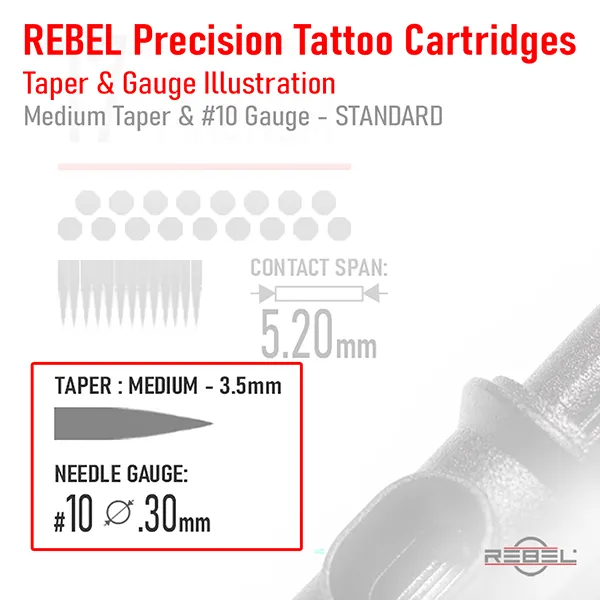

How to Read a REBEL Product Configuration Image

Each REBEL product image is designed to teach at a glance — not to decorate. What you see is real data, not filler. Every detail displayed has a purpose: to help artists make informed choices without guesswork.

Each visual element breaks down key performance information for that specific cartridge. Together, they form a clear and unified language that translates precision into something instantly understandable.

Here’s what every REBEL configuration image reveals:

-

Needle Count and Configuration Type — defines the number of needles and their purpose (liner, shader, or magnum).

-

Needle Configuration Illustration — a symbolic top-view layout showing how the grouping actually looks.

-

Contact Span Measurement — shows how wide the needle grouping contacts the skin during a single pass.

-

Taper and Gauge Specifications — define the needle’s shape, depth behavior, and pigment flow.

-

Macro Product Detail with the REBEL Logo — confirms authenticity and emphasizes craftsmanship.

Each of these data points appears consistently across all product visuals. As a result, artists can compare features instantly, select configurations confidently that fit their everyday tattooing style. This is how REBEL turns precision into a visual standard — clear, precise, and trustworthy.

Needle Count and Configuration Type

The large, unmistakable number indicates how many needles are in the configuration. Next to it, the configuration name spells out the type — whether it’s a Bugpin Liner, Round Shader, Magnum, or Curved Magnum. Red highlights signal that the needle gauge differs from the standard, marking either a Bugpin (#8) or Power (#12) variation.

Needle Configuration Illustration

Each illustration represents the actual needle layout — Round Liner, Round Shader, Magnum, or Curved Magnum. The pattern shown matches the real needle placement inside the cartridge. Magnums include two views: a front view to show their zigzag orientation, and a top view to distinguish between standard and curved layouts — so artists can identify them instantly, without reading a single line.

Understanding REBEL’s Contact Span

The Contact Span is REBEL’s term for the exact surface area a needle grouping covers in one skin pass. It combines what tattooists once called working width and working diameter.

Because it standardizes terminology, Contact Span helps artists predict performance and maintain consistency. In addition, it highlights how precision truly translates into reliability on skin.

To understand how Stroke and Active Span interact with Contact Span and affect performance, read What Is Stroke in Tattoo Machines? in The Rebellion Reads.

REBEL Precision Tattoo Cartridge Taper and Gauge Information

Since taper and gauge directly affect both ink flow and trauma, choosing the correct combination matters. For example, long tapers allow soft shading and smooth gradients, while standard tapers provide strong saturation and fast coverage in magnum configuration.

Therefore, the design of REBEL Precision Cartridges ensures a precise balance — speed without damage, depth without drag Furthermore, this control translates directly into faster healing and sharper healed results.

For a deeper dive, learn how taper and gauge choices translate to needle performance in Taper vs Bugpin Needles.

Apex-Level Precision in Every REBEL Cartridge

On closer inspection, REBEL craftsmanship stands out. Each needle demonstrates clean geometry, symmetrical alignment, and polished tips. As a result, these meticulous details prove why REBEL Precision Tattoo Cartridges stand at the true apex of tattoo cartridges — unmatched in consistency and performance.

Additionally, each needle is assembled in a clean-room environment under ISO sterilization standards and inspected under magnification before packaging. You can see this process in Tattoo Cartridge Manufacturing Pt. 10.

Apex Defined: The highest point reached by craftsmanship and precision — the place where REBEL stands.

The Apex Philosophy

Precision isn’t about complexity — it’s about control. Every REBEL tool exists to remove uncertainty, so the artist can focus purely on creation.

FAQ

What makes REBEL Precision Tattoo Cartridges the apex of tattoo cartridges?

They deliver pro-grade consistency and performance without the premium price tag — a balance that finally makes top-tier precision practical for everyday tattooing.

Are REBEL cartridges compatible with all tattoo machines?

Yes. They fit all major universal cartridge grips.

Conclusion

Why REBEL Stands as the Apex of Tattoo Cartridges

Tattoo cartridges began as a simple invention. Over time, they became the tools that defined precision. But REBEL Precision Tattoo Cartridges pushed that evolution further — they became the Apex of tattoo cartridges, built for reliability, consistency, and results that hold up long after healing.

Paired with REACH-Certified REBEL Black Tattoo Ink, they deliver ink smoothly and predictably, so tattoos heal clean — no fading, no patchy touch-ups, no wasted hours. That’s where the real value shows. Every tattoo that heals right is one less unpaid redo, one less setup to sterilize, and one more slot open for paid work. REBEL doesn’t just save money at checkout — it keeps earning after the tattoo leaves the chair.

Ultimately, when you understand your tools, every move of your needle becomes predictable — and predictability is precision.

This is the rebellion — for precision-driven tattooing.

The Apex isn’t the end of the climb — it’s the line we draw for everyone else to catch up.

Explore

Ready to dig in? Explore the full range of REBEL Precision Cartridges — designed for consistency and efficiency.

You can also compare configurations or request samples through Free Tattoo Ink and Cartridge Samples.

Read On

From here, learn more about Taper vs Bugpin or the relationship between Stroke and Active Span, and discover more industry insights in The Rebellion Reads.

Spread the Knowledge

If this article gave you clarity, share it with fellow tattoo artists and apprentices. The more we understand how our tools are built, the higher we can set the standards of tattooing.

Make Your Voice Heard by Leaving a Comment

Got questions or insights about today’s topic? Drop them in the comments — your voice helps push the craft forward.

Every REBEL cartridge is a reminder that precision is not a trend — it’s a responsibility.