LIVE - Rebellion Reads Posts

Tattoo Needle Manufacturing | Tattoo Equipment Evolution Pt. 7

Tattoo Needle Manufacturing

Tattoo Needle Manufacturing begins with a line of wire on an industrial spool. In fact, this starting point is not so different from a guitar string. Steel factories produce this wire from 304 surgical-grade stainless steel under controlled conditions to maintain medical-grade quality.

At this stage, the factory does not make tattoo needles. Instead, it creates wire for countless industries. For example, the same stainless steel may become guitar or piano strings, medical devices, strainers and mesh, or even rods, pipes, and beams. The tattoo industry simply claims a small part of this wide production.

Tattoo Needle Manufacturing: From Raw Wire to Needle Gauges

Industrial tattoo needles are mass produced with high-precision machinery. Tattoo needle manufacturers purchase these 1.5 mm diameter wires on spools from the steel factory. They must draw the material multi-stage drawing process to create the fine gauges used in tattooing:

Medical-grade stainless steel 304 has been widely studied in academic literature for its excellent corrosion resistance, sterilization compatibility, and material stability under repeated use.

- #8 (0.25 mm) – Fine (BUGPIN)

- #10 (0.30 mm) – Standard

- #12 (0.35 mm) – Thick (POWER Liner)

Think about it: from 1.5 mm down to 0.30 mm means reducing the size fivefold. As a result, the wire goes through several stages — 1.5 mm to 1 mm, then 1 mm to 0.75 mm, and so on until it reaches the final diameter.

Once the diameter is correct, cutting machines slice the wire into short sections 1¼ inches (about 30 mm). These machines produce thousands of identical rods in just minutes.

Creating the Needle Point: Tapering

At this stage, manufacturers handle only blunt, square-cut rods. To transform them into tattoo needles, the rods go through a shaping process called tapering. End milling machines gradually refine the rods in multiple steps until they reach the final form. This process involves shaping, stamping, milling, cleaning, washing, and polishing.

Tapering machines grind the square edge into a fine point step by step: short taper → medium taper → long taper → extra-long taper. Consequently, each taper length defines the performance profile of the finished needle.

This is the stage where tattoo needles are truly “born.” After tapering, next ultrasonic cleaners wash every needle, which is then dried and prepared for grouping.

Tattoo Needle Manufacturing – Building Needle Configurations

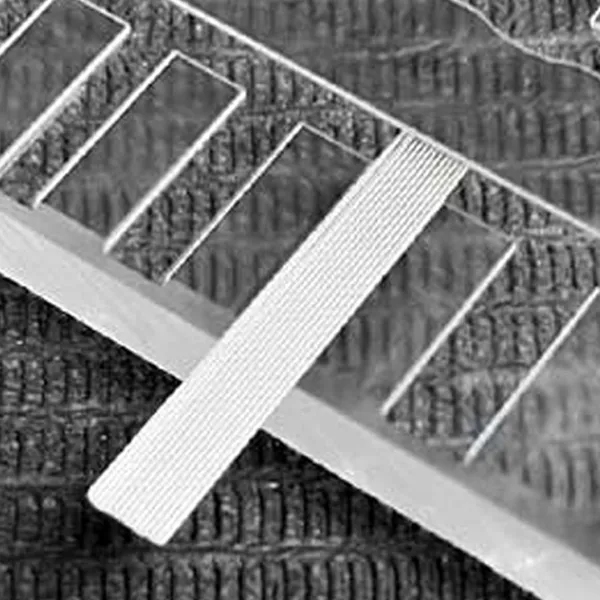

Needles with identical tapers are grouped into precise shapes based on their application: round liners, round shaders, magnums, or curved magnums. Precision jigs secure the needles in place while technicians solder them together, ensuring both accuracy and stability. Each configuration demands its own dedicated jig.

As a result of this grouping, the factory may hold 50–100 bins of needles, carefully separated by gauge and configuration. Strict organization is essential; without it, variations could easily mix and compromise quality.

Quality Control

Quality checks take place throughout the process:

-

After tapering: Inspectors examine each needle under a microscope. Any crooked, hooked, or imperfect tips go straight into the reject bin, since they would tear skin and cause trauma.

-

After soldering: Inspectors check finished configurations again to confirm stability and consistent shape.

Ultimately, thanks to these steps, only flawless needles move forward.

Final Assembly: Bars and Cartridges

Tattoo needles take two main forms:

-

Needles on bars (traditional) – Technicians solder configurations to steel bars, sterilize them, blister-package them, and box them. Although still available, this style sees less use today.

-

Cartridge needles (modern) – Technicians glue configurations to the plunger rod before assembling the housing. These cartridges undergo further steps before packaging, which we will cover in a later article.

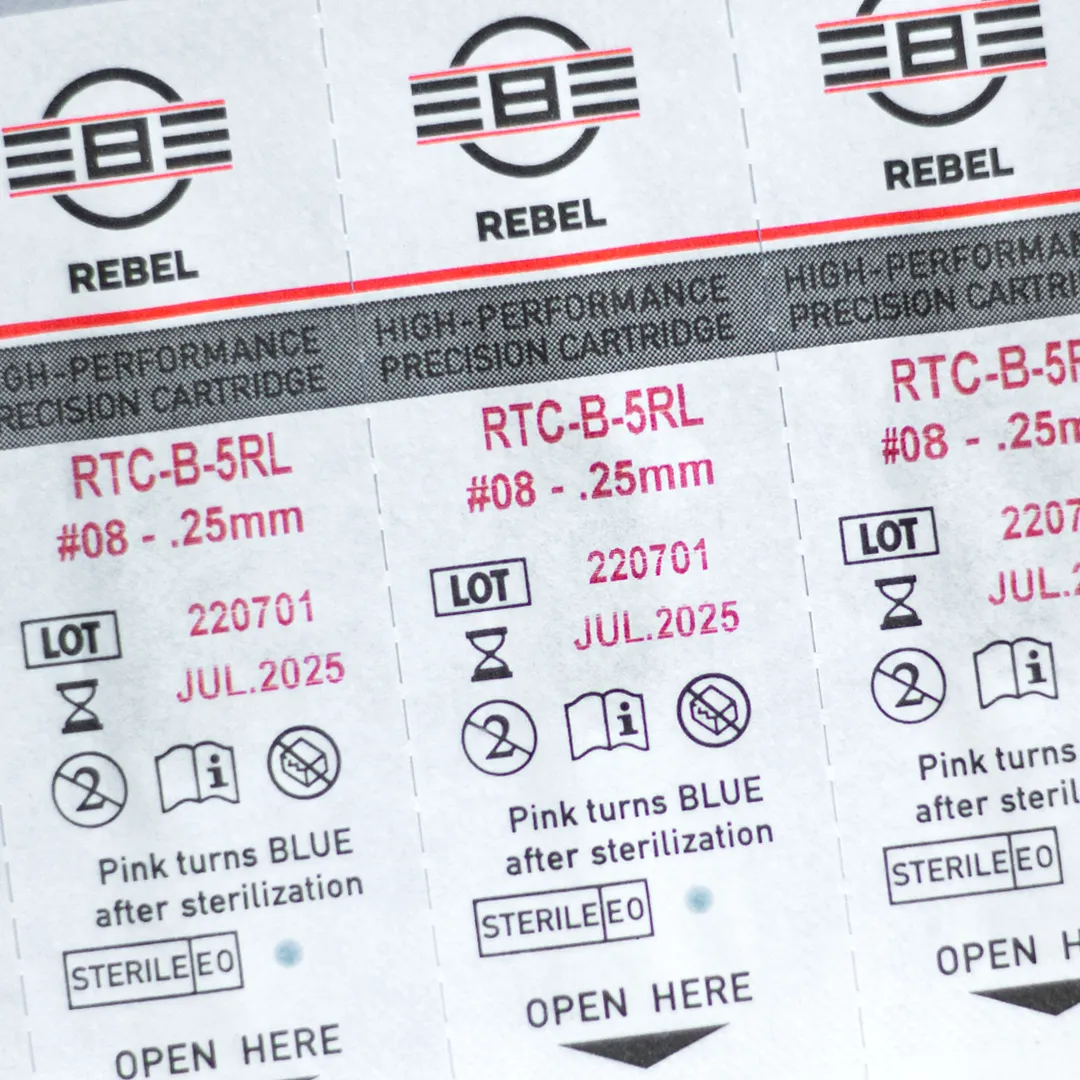

Finally, both types pass through EO gas sterilization after blister packaging to meet strict sanitary requirements.

Conclusion

From raw stainless steel wire to sharpened, grouped, and sterilized configurations, tattoo needle manufacturing demands precision at every stage. Careful engineering and strict quality control guarantee both performance and safety.

In the next chapter of the Tattoo Equipment Evolution series, we will explore Tattoo Cartridges and, in a following article, their full manufacturing process. These insights reveal how sharpened needle groups become the cartridges trusted by professional artists worldwide.

Careful engineering and strict quality control guarantee both performance and safety — the same standards that define every REBEL Precision Cartridge.

If you would like more industry insights, stay tuned to The Rebellion Reads.

◦ Caesar The Hun